Diagram of the possible components of a photovoltaic system

A photovoltaic system converts the sun’s radiation into usable electricity. It comprises the solar array and the balance of system components. PV systems can be categorized by various aspects, such as, grid-connected vs. stand alone systems, building-integrated vs. rack-mounted systems, residential vs. utility systems, distributed vs. centralized systems, rooftop vs. ground-mounted systems, tracking vs. fixed-tilt systems, and new constructed vs. retrofitted systems. Other distinctions may include, systems with microinverters vs. central inverter, systems using crystalline silicon vs. thin-film technology, and systems with modules from Chinese vs. European and U.S.-manufacturers.

About 99 percent of all European and 90 percent of all U.S. solar power systems are connected to the electrical grid, while off-grid systems are somewhat more common in Australia and South Korea. PV systems rarely use battery storage. This may change soon, as government incentives for distributed energy storage are being implemented and investments in storage solutions are gradually becoming economically viable for small systems.

Crystalline silicon is the predominant material used in 90 percent of worldwide produced solar modules, while rival thin-film has lost market-share in recent years. About 70 percent of all solar cells and modules are produced in China and Taiwan, leaving only 5 percent to European and US-manufacturers. The installed capacity for both, small rooftop systems and large solar power stations is growing rapidly and in equal parts, although there is a notable trend towards utility-scale systems, as the focus on new installations is shifting away from Europe to sunnier regions, such as the Sunbelt in the U.S., which are less opposed to ground-mounted solar farms and cost-effectiveness is more emphasized by investors.

Driven by advances in technology and increases in manufacturing scale and sophistication, the cost of photovoltaics is declining continuously. As well as North America with 440,000 systems in the United States, conversion efficiency of a conventional solar module increased from 15 to 20 percent over the last 10 years and a PV system recoups the energy needed for its manufacture in about 2 years. In exceptionally irradiated locations, or when thin-film technology is used, the so-called energy payback time decreases to one year or less. Net metering and financial incentives, such as preferential feed-in tariffs for solar-generated electricity, have also greatly supported installations of PV systems in many countries. The levelised cost of electricity from large-scale PV systems has become competitive with conventional electricity sources in an expanding list of geographic regions, and grid parity has been achieved in about 30 different countries.

As of 2015, the fast-growing global PV market is rapidly approaching the 200 GW mark – about 40 times the installed capacity of 2006. Top installers of PV systems in terms of capacity are currently China, Japan and the United States, while half of the world’s capacity is installed in Europe, with Germany and Italy supplying 7% to 8% of their respective domestic electricity consumption with solar PV. Solar power to become the world’s largest source of electricity by 2050, with solar photovoltaics and concentrated solar thermal contributing 16% and 11% to the global demand, respectively.

Schematics of a typical residential PV system

A grid connected system is connected to a larger independent grid (typically the public electricity grid) and feeds energy directly into the grid. This energy may be shared by a residential or commercial building before or after the revenue measurement point. The difference being whether the credited energy production is calculated independently of the customer’s energy consumption (feed-in tariff) or only on the difference of energy (net metering). Grid connected systems vary in size from residential (2–10 kWp) to solar power stations (up to 10s of MWp). This is a form of decentralized electricity generation. The feeding of electricity into the grid requires the transformation of DC into AC by a special, synchronising grid-tie inverter. In kilowatt-sized installations the DC side system voltage is as high as permitted (typically 1000V except US residential 600 V) to limit ohmic losses. Most modules (60 or 72 crystalline silicon cells) generate 160 W to 300 W at 36 volts. It is sometimes necessary or desirable to connect the modules partially in parallel rather than all in series. One set of modules connected in series is known as a ‘string’.

Scale of system

Photovoltaic systems are generally categorized into three distinct market segments: residential rooftop, commercial rooftop, and ground-mount utility-scale systems. Their capacities range from a few kilowatts to hundreds of megawatts. A typical residential system is around 10 kilowatts and mounted on a sloped roof, while commercial systems may reach a megawatt-scale and are generally installed on low-slope or even flat roofs. Although rooftop mounted systems are small and display a higher cost per watt than large utility-scale installations, they account for the largest share in the market. There is, however, a growing trend towards bigger utility-scale power plants, especially in the “sunbelt” region of the planet.

Utility-scale

Perovo Solar Park in Ukraine

Large utility-scale solar parks or farms are power stations and capable of providing an energy supply to large numbers of consumers. Generated electricity is fed into the transmission grid powered by central generation plants (grid-connected or grid-tied plant), or combined with one, or many, domestic electricity generators to feed into a small electrical grid (hybrid plant). In rare cases generated electricity is stored or used directly by island/standalone plant. Solar Star, Waldpolenz Solar Park and Topaz Solar Farm cover tens or hundreds of hectares and have power outputs up to hundreds of megawatts.

Rooftop, mobile, and portable

Rooftop system near Boston, USA.

A small PV system is capable of providing enough AC electricity to power a single home, or even an isolated device in the form of AC or DC electric. For example, military and civilian Earth observation satellites, street lights, construction and traffic signs, electric cars, solar-powered tents, electric aircraft may contain integrated photovoltaic systems to provide a primary or auxiliary power source in the form of AC or DC power, depending on the design and power demands. In 2013, rooftop systems accounted for 60 percent of worldwide installations. However, there is a trend away from rooftop and towards utility-scale PV systems, as the focus of new PV installations is also shifting from Europe to countries in the sunbelt region of the planet where opposition to ground-mounted solar farms is less accentuated.

Portable and mobile PV systems provide electrical power independent of utility connections, for “off the grid” operation. Such systems are so commonly used on recreational vehicles and boats that there are retailers specializing in these applications.

Building-integrated

BAPV wall near Barcelona, Spain

In urban and suburban areas, photovoltaic arrays are commonly used on rooftops to supplement power use; often the building will have a connection to the power grid, in which case the energy produced by the PV array can be sold back to the utility in some sort of net metering agreement. Some utilities, such as Solvay Electric in Solvay, NY, use the rooftops of commercial customers and telephone poles to support their use of PV panels. Solar trees are arrays that, as the name implies, mimic the look of trees, provide shade, and at night can function as street lights.

Performance

Uncertainties in revenue over time relate mostly to the evaluation of the solar resource and to the performance of the system itself. In the best of cases, uncertainties are typically 4% for year-to-year climate variability, 5% for solar resource estimation (in a horizontal plane), 3% for estimation of irradiation in the plane of the array, 3% for power rating of modules, 2% for losses due to dirt and soiling, 1.5% for losses due to snow, and 5% for other sources of error. Identifying and reacting to manageable losses is critical for revenue and O&M efficiency. Monitoring of array performance may be part of contractual agreements between the array owner, the builder, and the utility purchasing the energy produced. Recently, a method to create “synthetic days” using readily available weather data and verification using the Open Solar Outdoors Test Field make it possible to predict photovoltaic systems performance with high degrees of accuracy. Hydrophobic or hydrophilic) on soiling or snow losses. Microinverters (panel-level DC to AC conversion), module power data is automatically provided. Some systems allow setting performance alerts that trigger phone/email/text warnings when limits are reached. These solutions provide data for the system owner and the installer. Installers are able to remotely monitor multiple installations, and see at-a-glance the status of their entire installed base.

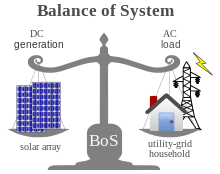

The balance of system components of a PV system (BOS) balance the power-generating subsystem of the solar array (left side) with the power-using side of the AC-household devices and the utility grid (right side).

A photovoltaic system for residential, commercial, or industrial energy supply consists of the solar array and a number of components often summarized as the balance of system (BOS). This term is synonymous with “Balance of Plant”. BOS-components include power-conditioning equipment and structures for mounting, typically one or more DC to AC power converters, also known as inverters, an energy storage device, a racking system that supports the solar array, electrical wiring and interconnections, and mounting for other components.

Optionally, a balance of system may include any or all of the following: renewable energy credit revenue-grade meter, maximum power point tracker (MPPT), battery system and charger, GPS solar tracker, energy management software, solar irradiance sensors, anemometer, or task-specific accessories designed to meet specialized requirements for a system owner. In addition, a CPV system requires optical lensesor mirrors and sometimes a cooling system.

The terms “solar array” and “PV system” are often incorrectly used interchangeably, despite the fact that the solar array does not encompass the entire system. Moreover, “solar panel” is often used as a synonym for “solar module”, although a panel consists of a string of several modules. The term “solar system“ is also an often used misnomer for a PV system.

Solar array

Conventional c-Si solar cells, normally wired in series, are encapsulated in a solar module to protect them from the weather. The module consists of a tempered glass as cover, a soft and flexible encapsulant, a rear backsheet made of a weathering and fire-resistant material and an aluminium frame around the outer edge. Electrically connected and mounted on a supporting structure, solar modules build a string of modules, often called solar panel. A solar array consists of one or many such panels. Inverter to convert the DC power produced by the modules into alternating current that can power lights, motors, and other loads. The modules in a PV array are usually first connected in series to obtain the desired voltage; the individual strings are then connected in parallel to allow the system to produce more current. Solar panels are typically measured under STC (standard test conditions) or PTC (PVUSA test conditions), in watts.

Module and efficiency

A typical “150 watt” PV module is about a square meter in size. Such a module may be expected to produce 0.75 kilowatt-hour (kWh) every day, on average, after taking into account the weather and the latitude, for an insolation of 5 sun hours/day. In the last 10 years, the efficiency of average commercial wafer-based crystalline silicon modules increased from about 12% to 16% and CdTe module efficiency increased from 9% to 13% during same period. Module output and life degraded by increased temperature. Allowing ambient air to flow over, and if possible behind, PV modules reduces this problem. Effective module lives are typically 25 years or more.

Fixed tilt solar array in of crystalline silicon panels in Canterbury, New Hampshire, United States

Solar array of a solar farm with a few thousand solar modules on the island of Majorca, Spain

Due to the low voltage of an individual solar cell (typically ca. 0.5V), several cells are wired (also see copper used in PV systems) in series in the manufacture of a “laminate”. The laminate is assembled into a protective weatherproof enclosure, thus making a photovoltaic module or solar panel. Modules may then be strung together into a photovoltaic array. In 2012, solar panels available for consumers can have an efficiency of up to about 17%.

Shading and dirt

Photovoltaic cell electrical output is extremely sensitive to shading. The effects of this shading are well known. If the current drawn from the series string of cells is no greater than the current that can be produced by the shaded cell, the current (and so power) developed by the string is limited. If enough voltage is available from the rest of the cells in a string, current will be forced through the cell by breaking down the junction in the shaded portion. This breakdown voltage in common cells is between 10 and 30 volts. Instead of adding to the power produced by the panel, the shaded cell absorbs power, turning it into heat. Since the reverse voltage of a shaded cell is much greater than the forward voltage of an illuminated cell, one shaded cell can absorb the power of many other cells in the string, disproportionately affecting panel output. For example, a shaded cell may drop 8 volts, instead of adding 0.5 volts, at a particular current level, thereby absorbing the power produced by 16 other cells.

Several methods have been developed to determine shading losses from trees to PV systems over both large regions using LiDAR.

Describe your needs and we will offer you the best solution